Technology

Felicia Design keeps up-to-date or even develops technology. Machined parts, model making, product development, software, machined finishes, and laser applications are some areas where, in the past, we have developed technology. Technology is used to increase the available production options, decrease production times and provide higher quality.

Our innovative approach to problem solving is one of our strengths.

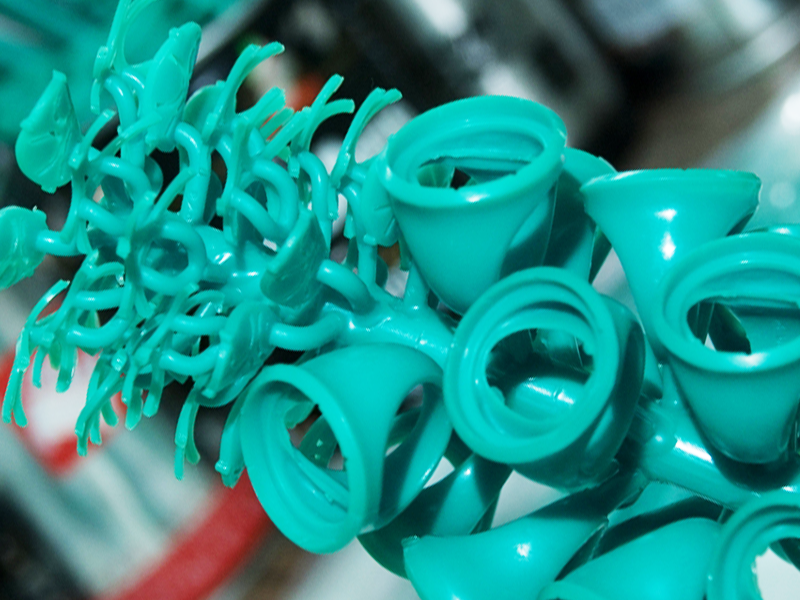

Model Making and Metal Masters

All design work, CAD, wax models and metal masters are done in-house. We offer these services at a fair cost. We take great care to protect our clients’ intellectual property, as well as to create a product that accurately represents the brand or concept.

Metals and Casting

Casting is sub-contracted to trusted working partners. We cast in gold and in 925 Sterling Silver. We work only with high quality materials sourced from trusted suppliers.

In our alloys we do not use Cadmium, Lead, Nickel or any prohibited and harmful materials. We follow European rules and regulations (REACH).

We are a certified member of the Responsible Jewellery Council. This means we have been audited by an independent third party with respect to general compliance with all laws, and with special focus on responsible supply chains, human rights, labour rights and working conditions, health and safety, environmental management and product disclosure.

For more info, please visit www.responsiblejewellery.com

Galvanic Treatment

All plating is sub-contracted to trusted working partners. We can guarantee the micron with a certificate if required.

In our alloys we do not use Cadmium, Lead, Nickel or any prohibited and harmful materials.

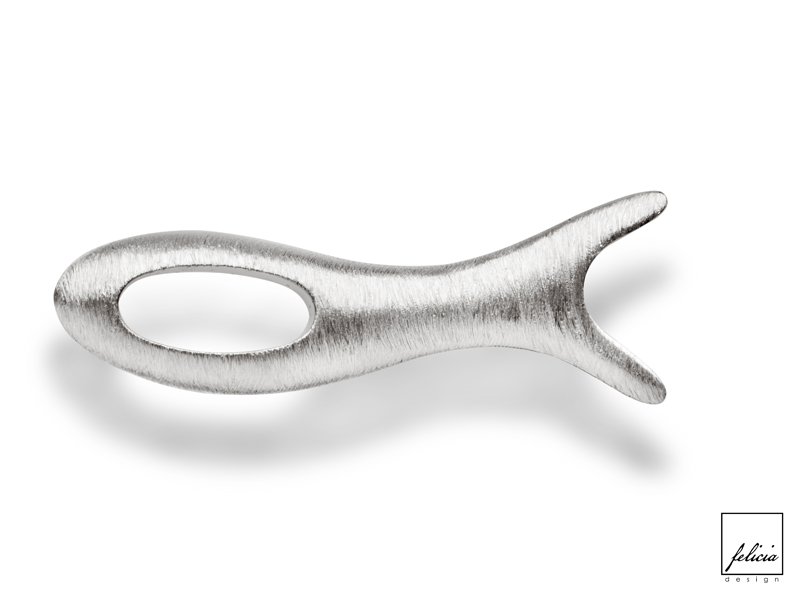

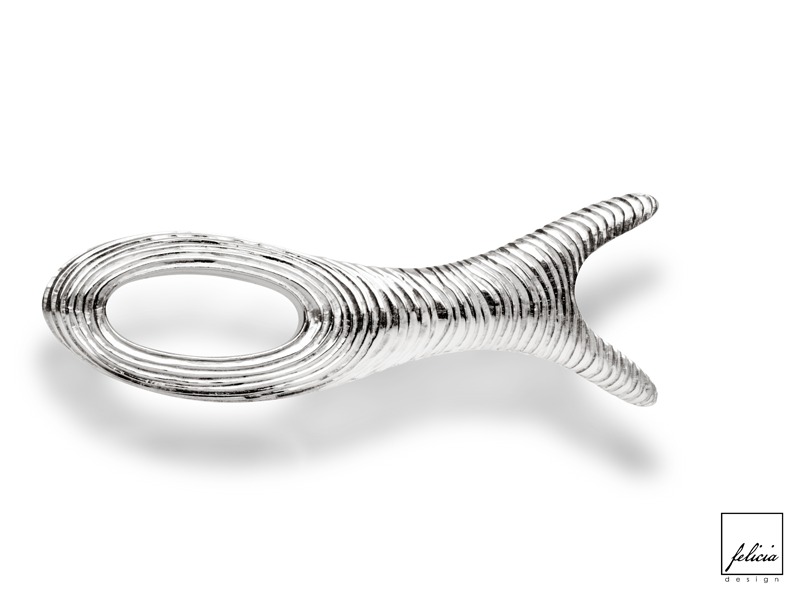

Textures and Surface Finishes

Our technical knowledge in abrasives and metal finishes is renown. Our production and design teams have developed a wide catalog of options of textures and looks. We offer more than 50 surface options from shiny to matte, carved, textured, embed, satin, water blast, semi-finished, aged looking and many others.

Please Note: Our sample collection of fish with different surfaces demonstrates what we can do in metal finishing. The customer can see, touch and feel these pieces. Attaining the chosen surface finish requires balancing multiple considerations, including the target number of pieces and the desired final results. For example, some textures require embedding in the master.

Our team can help you choose the best solution and explain how it will be achieved.

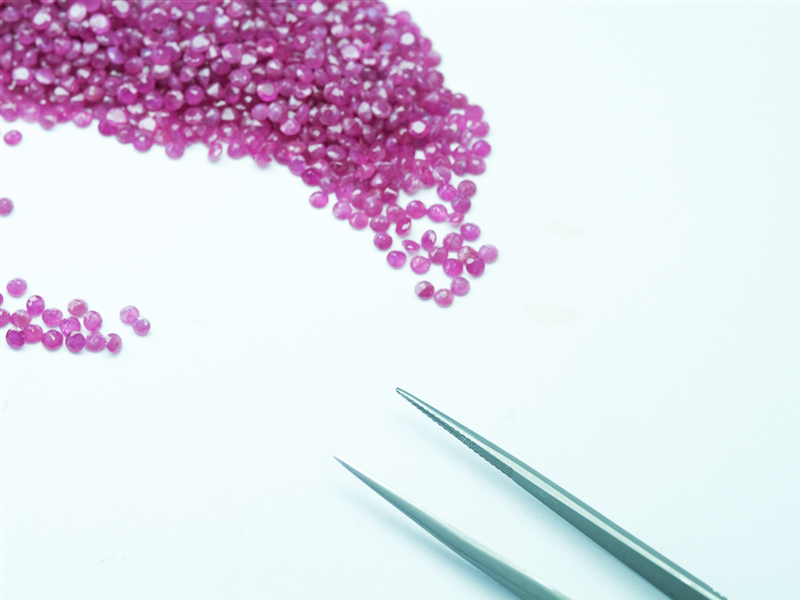

Gemstones, Special Stones, Other Materials

Color, cut, clarity and carat are standards for grading all gemstones. The four criteria carry different weight depending on whether they are applied to colored gemstones or colorless diamonds.

In addition to natural stones, we work with synthetic (lab created) stones and simulated (imitation) stones, including the newest nano stones. They can have very beautiful color and luster and look like natural gemstones. Another alternative for trendy fashion.

We also work with other materials, such as amber, pearls, hematite, jade, leather, shell, etc.

All Felicia Design materials are sourced from trusted working partners.

We work with the following:

Diamonds

Natural Stones

Synthetic Stones

Simulated Stones

Other Materials

Stone Cuts

Gems come in two different styles, faceted and non-faceted.

Faceted gems have geometrically-shaped, flat polished faces, like the picture here. Non-faceted gems are polished but not necessarily geometrically-shaped, and have no flat polished faces.

The shape and quality of a rough gemstone influences how it will be cut, which affects its value. The cut determines how well a gem returns its body color back to the eye.

Setting and Design Styles

Brands and designers can choose from many different styles and elements for for their collections.

For example a ring can have different profiles, setting styles, prong counts or design details - like whether to engrave or enamel or filigree. Each of these has sub-options which can be mixed and matched to create original pieces. We are well versed in all the techniques used for the different styles.

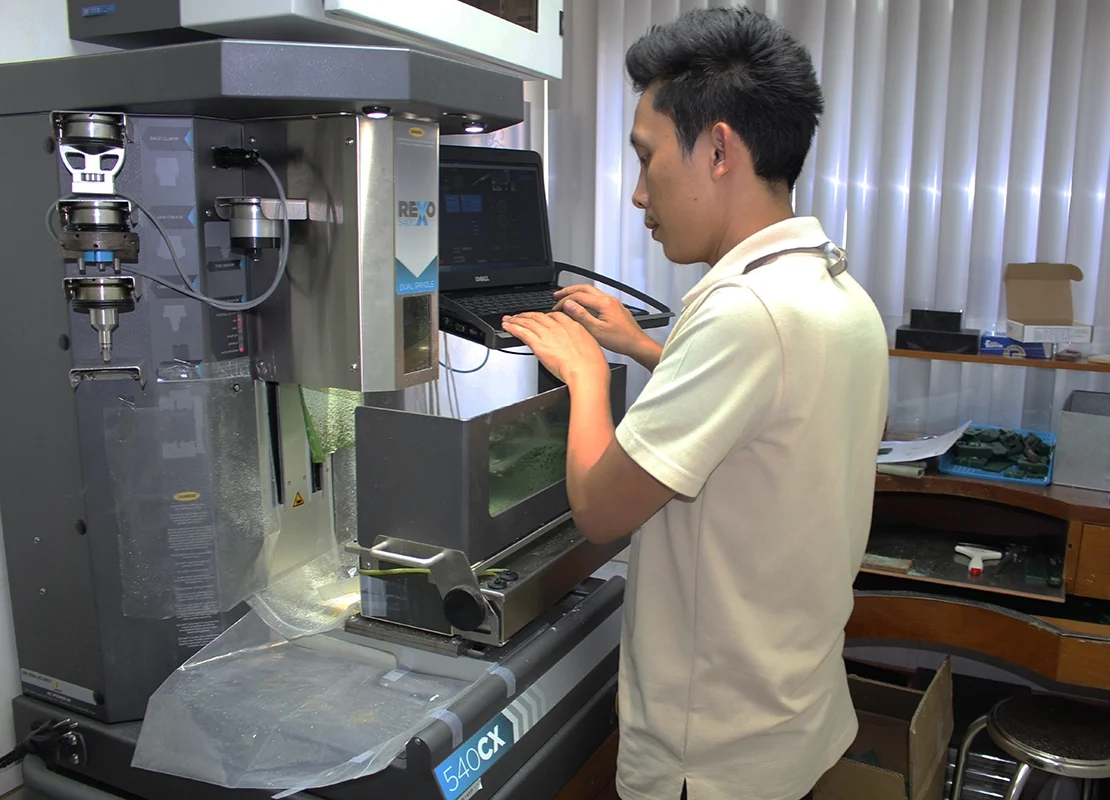

Laser

Felicia uses the latest European technology.

We use lasers whenever possible for the soldering and engraving processes.

Soldering and Metalsmithing

Felicia Design often uses soldering for chains. We also use soldering in different phases of jewelry production. We do not use harmful substances or dangerous processes. We achieve solder-less, seamless welds on all metals with little or no heat, which allows us to work very close to heat sensitive stones.

Other specialty metalsmithing techniques include chasing and repoussé, etching and engraving, electroforming and electroplating, raising, reticulation, casting and bezel setting. Finishing techniques such as filing, buffing and polishing have the support of our long trade experience and of some technical innovations developed by our teams.

Epoxy Enamels

Also called "resin" or "cold enamels" this technology is the easiest and most practical way to apply vibrant color to a surface. Well known for its high strength on many different materials, the best results are always achieved with metals.

The origins of enameling date back thousands of years. The old techniques used glass, and required high temperatures and specific ovens, hence the name "fire enamels." Cold enamels began being used in the jewelry industry more than 60 years ago, and as the name describes, they do not require hot, melting temperatures.

The ability to mix colors like paint allows this material to match Pantone colors. Designers have more options than ever to express their creativity.